A Bolton firm's innovative technology is destined for the African nation of Ghana, to boost that country's agricultural economy. Hygrex Technologies signed an agreement Oct. 15 with the Aflao region in Ghana to provide technology and expertise in food processing. This technology will reduce the amount of spoilage in post-harvest losses and enhance the region's export potential.

On hand to sign the precedent-setting memorandum of understanding was Torgbui Ameny FITI V, Paramount Chief of the Aflao region. He warmly embraced Hygrex's commitment to his country and pointed to the very real need for this type of technology.

?Post harvest loss is a major problem in Ghana and accounts for 35% of total agricultural output,? he said. ?This is due to the lack of technology in extending the shelf life of agricultural products for storage and export. This situation perpetuates the problem of poverty in the agricultural sector, even though a large available harvest exists.?

The Hygrex technology is able to effectively dehydrate these products to significantly extend shelf life for local consumption and export. The Hygrex system does not use heat to dry the products, thus preserving the nutritional value. Water removed from the products (which is distilled) can also be stored for future use or exported to other regions.

Kodjo Peterson-Midadje (aka Torgbui Duneyo Midadje I, Senior Divisional Chief of Aflao) said they first encountered Hygrex's technology some three years ago and realized its potential for his country. ?This technology is so vital to our agricultural economy,? he stressed, adding it will benefit his region both on the small scale as well as help increase the country's GDP, which is estimated at more than $35 billion (1999 figures). The byproducts from the process (skin of peeled fruits) can be used again to feed livestock and the water extracted can also be used, bottled and sold.

He said if the Canadian government can assist Hygrex in setting up a plant in his region, it will go a long way to helping the economy of Ghana. He used the age-old sentiment of giving people fish and teaching them to fish, noting such a system will help his people become more self-sufficient. Chief FITI V said he's very happy to secure this technology and hopes are to have it installed by 2004. The process will help farmers preserve their products for future use and shipping. He said he's appealing to government and agricultural groups to see Hygrex's custom-made devices and witness first-hand their benefits. He hopes a compromise can be reached in making a site (plant) in his region a reality.

His farmers are suffering, even though they produce a great deal. Storage and spoilage are the main hurdles and Hygrex's technology offers a solution. This first plant will be a model for all other regions in Ghana to emulate. He extended his personal thanks for the efforts made to bring such a development to his towns and regions.

Local studies have shown the increase in value for each tonne of harvested product would increase by two to four times. GDP for the country would be positively impacted and employment opportunities would also increase for both harvesting and processing.

?The mutual goal in this region is to transfer the Hygrex technology to the regions in Ghana so even further economic development and employment opportunities can be realized,? said Erwin Spehr, Hygrex president.

He said the long-term system he has in mind for Ghana would be a plant and 10 Hygrex machines, processing an estimated 30 tonnes a day.

He said the United Nations has shown interest and he hopes a foothold can be established in Ghana and then expand to other parts of Africa. Spehr said despite the innovative technology, the company can't do it on its own. They require a financial commitment and partners such as the Canadian government, UN and Ministry of Agriculture and Food. The price tag of this plant is estimated to cost between $4 and $5 million.

Spehr called the Oct. 15 agreement a ?fantastic marriage between Ghana and Hygrex.?

The memorandum is for one starter machine.

Post-harvest loss is a major problem in Ghana, located on the southern coast of West Africa. It comprises 88,700 square miles and is home to roughly 19.8 million people. The main crops of Ghana include cocoa, coffee, rice, cassava, peanuts and corn.

The main cause of post-harvest loss, which accounts for 35% to total agriculture output, or 21.5% of GDP, is due to the lack of appropriate technology for processing farm produce from primary stages. Most farmers become discouraged or put out of business after being forced to sell their produce below production costs during bumper harvests. Such events actually perpetuate the vicious cycle of abject poverty among the farming communities across this country.

Ghana is still storing or exporting hundreds of tonnes of yam, plantain, fruits and other commodities in their raw state. The values of these drop drastically during the harvest season and sometimes have no available markets.

Hygrex said strategically locating its versatile processing equipment in the farming zones would effectively provide a sustainable solution to this perennial problem.

Post-harvest preservation takes several forms from traditional methods to modern processing and packaging. The least expensive is sun drying, however, this exposes the products to the sun and the heat destroys vitamins and enzymes. Refrigeration is another option, but the physical space requirements, cost and unreliable power supply make it cost-prohibitive. Dehydration is more attractive to the small-scale enterprises for preserving tropical produce.

Hygrex's system uses super dry air for specialized drying applications, removing water from the fresh product. With this application, water is basically the only element removed; no heat is involved; vitamin and enzymes are preserved; food can be stored for a long time for export and food can be stored without refrigeration.

The food can then regain its original freshness simply by adding water. The impact on the local economy would reduce the post-harvest loss by 90%. The memorandum of understanding reads, in part, ?The parties agree that the present MOU should be realized within a time frame of one year. It is our mutual understanding that the first 20kW machine with a drying capacity of 3 tons per day of cassava should be installed by September of 2004 in support of the presidential cassava initiatives.?

Hygrex Technologies is a Canadian developer and manufacture of closed-loop drying systems for various applications. These include food processing, drying of automotive and industrial paints, processing of waste and sludges for commercial and municipal applications. The unique technology utilizes very little energy, provides no exhaust and has been recognized as an environmental enhancement.

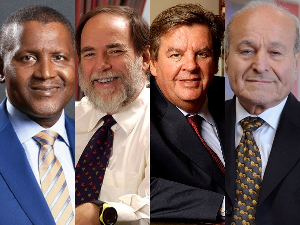

Photo Caption: Torgbui Amenya FITI V, Paramount Chief of Aflao, Ghana, signed a memorandum of understanding with Bolton's Hygrex-Spehr Industries for its innovative technology. Erwin Spehr also signed the agreement, while Rick Laanvere of Hygrex and Kodjo Peterson-Midadje (aka Torgbui Duneyo Midadje I, senior divisional chief of Aflao) look on.