The local Food processing industry in Ghana is still budding and requires boosting in order to meet required standards, offer consumers high-quality products and owners good profit margins. The food processing sector is largely found in the informal sector operating mainly as small and medium scale enterprises (SMEs).

In Ghana, readily available data on SMEs are scarce, but statistics from the Registrar General’s Department suggests that 92 percent of companies registered are SMEs providing about 85 percent of employment and, contributing 70 percent to Gross Domestic Product (GDP). The dispersion of SMEs promotes better distribution of income and generates additional value in raw materials and products.

Quality processing of food products that meet international standards for both local and foreign consumption is lacking in this sector. Problems of unsuitable packaging materials, inadequate and effective storage especially during transportation and the high cost of raw materials hinder the progress of the food processing sector. The lack of standards and specifications also cripple the industry which has great income-generating the potential for business owners.

To address some of the challenges confronting the sector, a Ghanaian food scientist Mavis Owureku-Asare, is empowering food processors with the needed skills, knowledge and resources to help strategically position their products and attract local and international markets. Mrs. Owureku-Asare has a wealth of experience in food product development and postharvest management (PHL) of fruits and vegetables.

She has knowledge of local and international food standards such as in Codex Alimentarius, International Organization for Standardization (ISO) and Ghana Standards. She is also certified in FSPCA Preventive Controls for Human Food regulation.

She is currently a 2015 Borlaug LEAP fellow and visiting scholar at the Department of Agricultural and Biological Engineering, Purdue University in Indiana USA. As a fellow of African Women in Agricultural Research and Development (AWARD) her research is gender responsive and focused on promoting practical agricultural technologies and solutions which benefit smallholder farmers and improve livelihoods of women in Ghana.

Mrs. Owureku-Asare is the CEO of Kasmalink Consult, a non- profit consultancy aimed at helping food processors position their products, boost production and stimulate demand. She works with small scale food processors on product formulation, food quality analysis, branding and food packaging to help create a competitive advantage for them. She collaborates with a network of sponsors and research scientists who volunteer their time, expertise, and money to support these processors and entrepreneurs.

She believes that giving the chance, opportunity, and support, women can contribute substantially to the development of the food processing industry in Ghana. She has worked on food products such as “sobolo” (Hibiscus drink), cereals such as “tombrown”, “shito” (pepper sauce), and some local snacks and confectioneries. She admits that the local food industry is a very lucrative one, and calls on Ghanaians to patronize locally processed foods which are more nutritious and healthier than some imported foods.

“We can begin by feeding our families especially our children with some locally processed cereals and snacks such as “asana”, “nkati cake”, “kube toffee”and “adakoa” which is made from maize, ground nuts and spices and highly nutritious than some processed snacks imported into the country”.

She stresses the need for capacity building for processors and is on a quest to promote the production and consumption of locally processed foods. She is calling on government and other stakeholders to take a strategic look at the local food industry by providing technical support for food processors in the industry so they can produce healthier and more hygienic foods that appeal to consumers.

Cee ChoCho – an entrepreneurial couple of husband and wife have been making plantain chips since 2005. The production of Cee Chochoo plantain chips started on a table top with a coal-pot, however after a few years in business, the pace of production and sales have tremendously improved.

They plan on expanding and setting up in plantain growing areas so they can have direct access to plantain supply, thereby; reducing the cost. High post-harvest losses occur along the plantain value chain when moving plantain from production areas to the capital-Accra (where business is set up). During the lean plantain season (April to August) it is difficult to get plantain, and this affects production and profits. It is prudent to process when the plantain is in season so as to reduce the losses incurred.

Operating for over a decade, Mr. Henry Nortey says coming into contact with Kasmalink Consult has improved their business and gained them the needed leverage to serve foreign markets. Sales were previously mainly local and they catered for domestic parties, funerals, and conferences. Mr. Henry Nortey testifies to a domain expansion and is now serving orders from the United States and the United Kingdom.

A day’s turnover is around GH¢300 – GH¢500.00 and on a good day GH¢500.00 - GH¢1,000.00. The processes employed in the production of plantain chips are performed manually, labour intensive and time-consuming.

There is the need for mechanization of current processes as well as setting up storage facilities to manage the growing market for their products. Cee ChoCho is hoping to forge any partnership that will inject some capital into their business to acquire equipment that shreds plantain so as to facilitate greater production to meet demand both locally and internationally.

Comfort Teye, a toffee seller says working with Kasmalink Consult has benefited her business immensely, noting: “My business was supported with product formulation, shelf life assessment, sensory evaluation and labelling which initially was non-existent”. Teye, who was spotted by Mavis on the streets of Accra, emphasised that Kasmalink Consult created market opportunities and a direct link to clients so she no longer sells on the streets of Accra.

She wholesales her candies to other retailers who sell her products. Kasmalink also uses social media platforms to promote her business which boosts income. She now makes GHS 250-400 profit daily as compared to her previous daily earnings of GHS 20.

Empowering entrepreneurs with the required skills assistance will help strengthen the local food sector and boost food production in Ghana.

Business News of Saturday, 4 June 2016

Source: Hinneh, Samuel

Food scientist creates competitive advantage for food processors

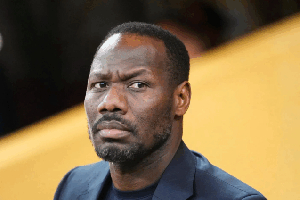

Mavis Owureku-Asare-Food scientist

Mavis Owureku-Asare-Food scientist