Prior to the outbreak of COVID-19, many cities in developing countries were struggling with managing plastic waste. The situation has been compounded by the improper disposal of face masks. Many environmentalists have called for proper measures to tackle the reckless and indiscriminate disposal of used face masks.

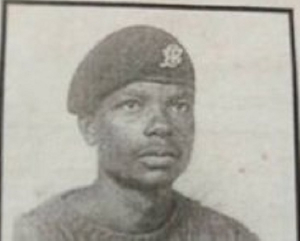

In Kenya, environmentalist Francis Thuti is leading the way in the recycling of used face masks. Credited with conducting groundbreaking research on how to conduct a zero-waste project, Thuti converts the used face masks into building blocks.

“During this Covid-19 pandemic, there are lots of face masks lying around and I heard people say that they cannot be recycled. I have changed that perception,” Thuti told The Nation.

He sorts out face masks, plastic bottles, glass bottles, polythene papers, and woven carrier bags from a dumpsite near his workshop where he has been conducting his research. Using an improvised crushing machine, he crushes the glasses into sand form.

He then combines the waste items and heats them at a high temperature, after which he adds the glass sand to precipitate the merging of the components. Thuti then condenses the product to produce heavy-duty blocks which could be used as building blocks.

His products have been tested by Kenyan’s Ministry of Transport, Infrastructure, Housing, Urban Development, and Public Works. The laboratory report generated by the ministry endorsed Thuti’s building blocks.

The environmentalist said he has used the blocks, which weigh about 2.5kg, to cover a walkway of 50 meters. “A piece of square meter cabro weighs 2.5 kilograms.

I have used the cabro blocks to cover a walkway of 50 meters at Nanyuki Water and Sewerage Company (Nawasco) offices. This is just a starter of my innovation and they look magnificent and durable,” he said.

Besides producing blocks, Thuti also uses the same materials to produce interlocking building blocks, which are in the prototype stage. He hopes to venture into mass production. “I will also conduct research to determine the exact weight of ingredients used to manufacture a piece of a building block. Once fully operational, this will be a win-win situation to the conservation environment even as we construct our roads and houses,” Thuti said.

The environmentalist is planning to expand his plant at his dumpsite once the full operation starts. The expansion, he envisages, will create some 200 jobs.

“I will soon require more staff to sort out wastes in the dumpsites in the urban centers, hotels, hospitals, ranches, and markets. The manufacturing process will also require lots of manpower during mass production. We estimate to bring 200 people on board,” he said.

For now, finance remains a key challenge. Thuti is hoping the Kenyan government will support him with experts and research funds in his quest to not only conserve the environment but to create jobs for the youth.

Africa News of Friday, 28 May 2021

Source: face2faceafrica.com